How did we approach this project?

Entry into a two-phase contract

Given the scope and complexity of the project, ALSÉÉN and Rijkswaterstaat opted for a two-phase contract. Unlike a full UAV-GC contract, where the entire project is sold for a fixed price, this project is divided into two parts. The more straightforward components are sold at a fixed price, while the complex parts are further developed in collaboration with the client during the design phases.

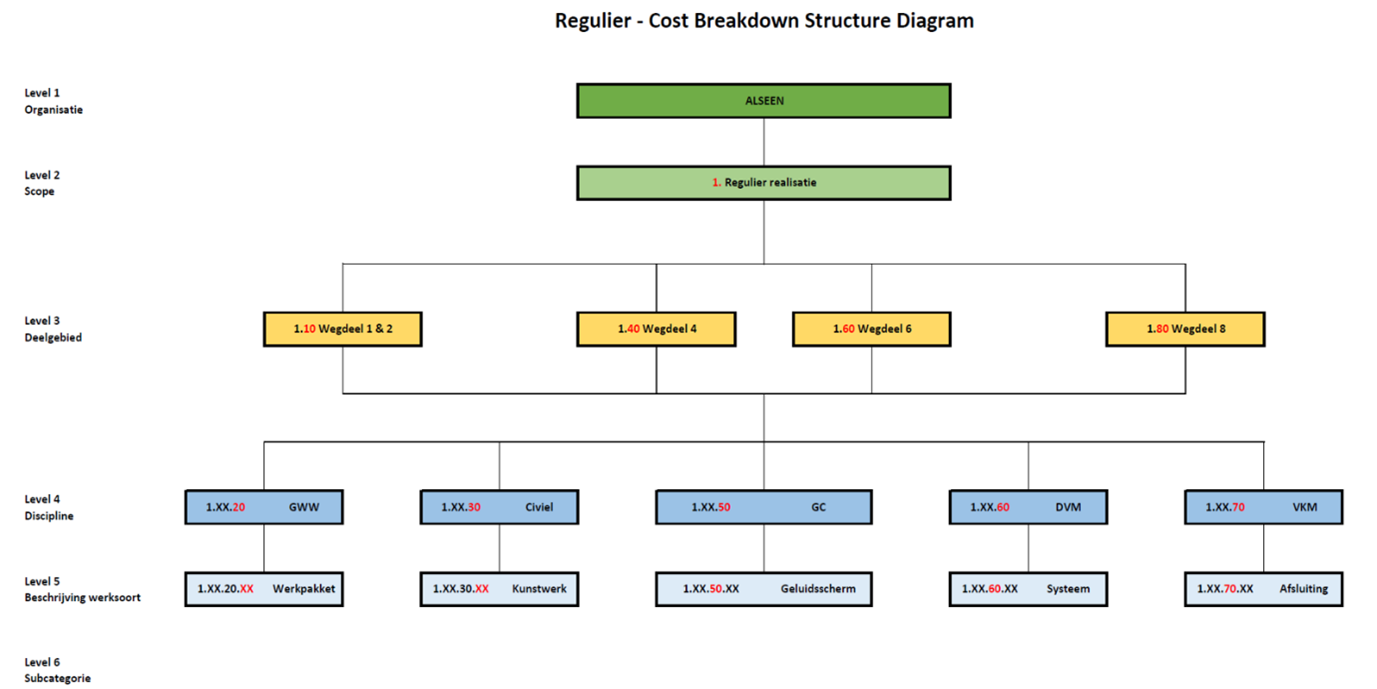

Strategically establishing a Cost Breakdown Structure

The multidisciplinary nature of the work and the contract form present challenges in cost management. By utilizing the flexibility in the structure of the CBS, we have enhanced recognizability in work budgets by using recurring codes for similar work packages. As the project progressed, the work budgets were adjusted to integrate the new procurement and execution strategy. This made the costs transparent and traceable for the entire project team.

Coordinating cost monitoring

Costs are recorded in the financial systems of Ballast Nedam, which include the CBS structure. By exporting this data to Excel, costs are monitored and compared against the budgets of the work packages. Using Earned Value Management (EVM), the project’s progress and budget performance are tracked. To also integrate the schedule and risks, key scheduling rules and the top five risks for each subproject have been added to the cost monitoring process. Through this we enable an integrated project controls approach within cost control.

From monitoring progress to dynamic financial insight

During the construction phase, it became essential to identify and monitor critical cost items. This was accomplished by analyzing where the greatest risk of cost overruns lay and where costs could be effectively controlled. A dashboard was developed for these cost items, providing an overview of the budget, current costs, and the estimated costs at completion (EAC), enabling better management of financial risks.